Home / Blog / 6 technologies that will change the face of saudi construction

SUMMARY

When you think of technological advancements, the construction sector doesn’t automatically come to mind.

In the Kingdom, despite the amount of ongoing construction work, the industry is still young and in the process of development. It has been slower than others to embrace digitalization, with more pressing concerns, like solving the problem of a shortage of skilled labor.

As the world faces the disruptions brought on by 2020 to the construction industry, keeping a narrow and traditional view will be detrimental to your evolution. The writing is on the wall – building companies need to reinvent construction methodologies if they want to remain relevant. Professionals need to start thinking outside the box to implement new sustainability regulations, as well as incorporate advancements in information technology to construction planning, design, and implementation.

But how do you do this? By integrating digitalization processes like BIM software across construction, introducing Artificial Intelligence, IoT, Augmented Reality, and smart devices, you can change the way you conduct your business. Additionally, using sustainable building materials from prefabricated and 3D printed sources can help you create efficiencies in operations, facilitate effectiveness, and find new opportunities for growth.

INDEX

- Drones

- 3D Printed, modular and prefabricated construction

- Building Information Modelling software

- Mobile technology, IoT, and smart devices

- Virtual, Augmented, and Mixed Reality

- Advanced constructional materials and resources

6 TECHNOLOGIES THAT WILL CHANGE THE FACE OF SAUDI CONSTRUCTION.

Whilst disruptions to industries are common, the 2020 coronavirus pandemic has pushed the need for technology and digitalization across all sectors of the economy, including construction.

Take China for example. The world watched in awe as the country battled the COVID-19 virus by putting together a 1000-bed hospital in ten days. They then started and completed work on a second hospital that was patient-ready a week later. Such astounding deliverables were previously unheard of in traditional construction industries. However, as the virus spread across the world, countries were forced to reinvent resources to meet needs.

The events in China and the world over have given rise to a global conversation that discusses the scope and potential of building design technologies, offsite manufacturing, modular construction, and incorporation of new digital technologies in everyday building.

This article discusses the innovations changing the face of construction globally, as well as in the Kingdom.

Conservative industry

As construction projects take years to plan and complete, the industry, in general, is hesitant to embrace emerging technologies. As builders incorporate technologies like virtual reality, autonomous drones, artificial intelligence, concrete three-dimensional (3D) printing, they are beginning to realize the power and potential these new technologies can bring to a site and a project.

These advancements are adding value by optimizing efficiency and productivity in construction, from planning and execution to deliverables.

Listed below are six of the leading technologies that hold vast opportunities for construction work in the Kingdom:

- Drones

Of the tech advancements being incorporated in the construction industry, drone technology is gaining a lot of traction. Construction drones, for example, are achieving great results including monitoring worksites for equipment malfunctions and security breaches, performing topographical mapping surveys for roughly 1/20th the standard cost, and increasing worker safety by 55%[1].

Using photogrammetry, skilled technicians can use drones to collect data by flying them over a site and taking high-resolution photographs, and from these images extracting high-quality point clouds and 3D models. Additionally, they often deliver results with fewer errors, as well as reduce work timelines from months to days, and even hours, in some cases.

With the advent of machine intelligence, drones are becoming smarter and more capable. Real-time obstacle avoidance, gesture recognition, and fully automated flight are making drone use even more effective and useful across construction sites. Autonomous drones, for example, are being used to map sites, survey hazardous and remote spots to deliver worker security as well as more accurate data. By cutting down on the errors that can cause delays and increase costs, drones have the potential to drastically improve the speed, accuracy, and safety standards of many parts of the construction cycle.

In fact, a report by Construction Week states that drones being used in KSA construction have the potential to reduce manual rework by 25%. This can help developers avert costly errors by identifying slip-ups prior to, and during construction.

- Drone-mounted LiDAR: LiDAR or light detection ranging sensors mounted on construction equipment and drones can scan the surrounding worksite and produce high-resolution 3D images in real-time. This makes it possible to perform site work from a distance, reducing or eliminating the likelihood of worker accidents.

- 3D Printed, Modular and Prefabricated Construction

3D printed, and modular, prefab houses are changing the timelines and costs involved in building houses internationally. Even within the Kingdom, construction technology is gaining popularity. International construction contractors are making themselves more marketable by creating design libraries of products for residential, commercial buildings, hospitals, and retail projects to offer a suite of customizable options.

- 3D printing: 3D printing technology holds huge potential for the construction industry in Saudi. It can speed up deliverables, as well as reduce costs. The use of 3D printing also makes it possible to embed wireless sensors into the walls of a property to achieve full technological integration. These 3D-printed structures are being designed in such a way that they are not only more sustainable, kinder to the environment, and energy-efficient, but they can also incorporate IoT to help construct smart structures.

- Prefabricated construction: Whilst modular and prefabricated construction isn’t actually a new concept, its design quality and execution haven’t always been successful. In 2020 however, especially as governments rushed to set up structures to house, treat and isolate patients with COVID-19, prefab buildings are making a huge comeback. They are cheaper to construct, and more durable, and quicker to build than traditional buildings. Additionally, unlike conventional construction where the needs and tasks change rapidly, prefab materials use component-based assembly production, where construction work becomes easy when done repeatedly. This means that a builder can set up a project faster with fewer people. Because of this prefab construction design methodology, the technology holds huge attractions for buyers and has the potential to revolutionize the way Saudis build their homes.

In fact, Katerra, a Silicon Valley-based construction technology start-up, has just recently signed an MOU with the Saudi Ministry of Housing to build 500,000 homes[3] in the next 10 years using 3D printing technologies and prefab construction materials.

- Building Information Modelling Software

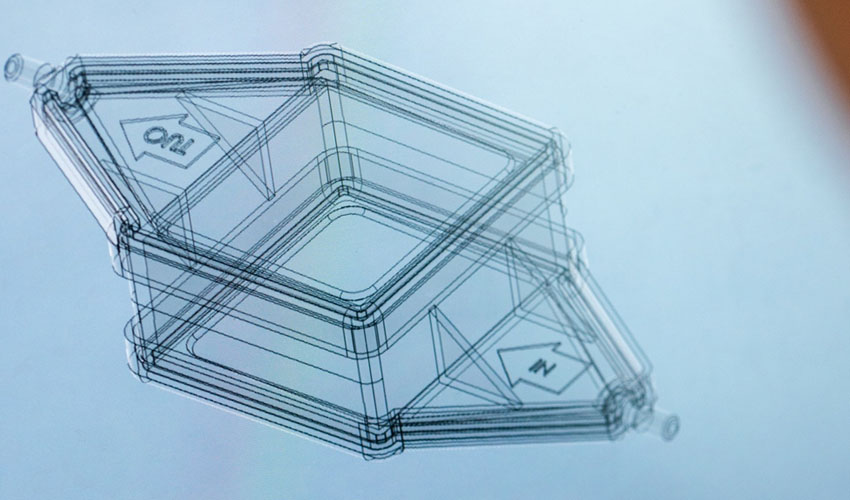

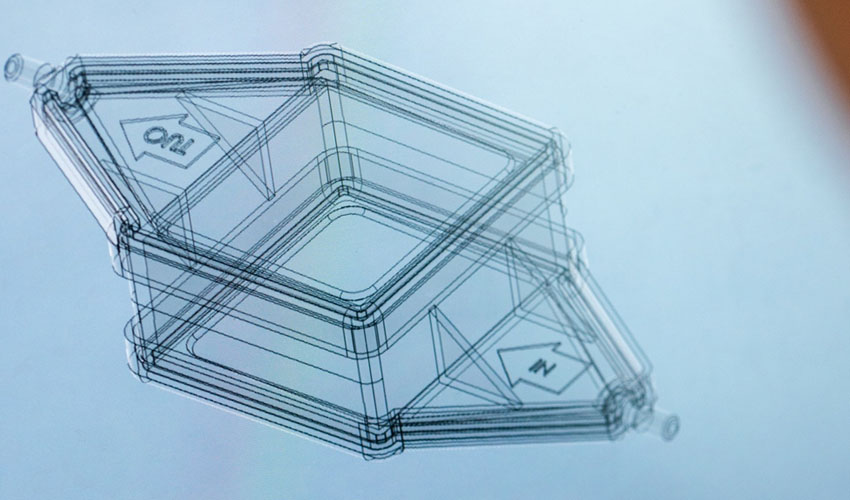

Building Information Modelling (BIM) is the application of different digital processes like IoT and Augmented Reality (AR) technologies to generate “smart” management and workflow planning tools. These integrated tools allow you to create an intelligent 3D model of the project and generate smart workflows around it even before a single brick has been laid. This results in an elevated construction experience at all stages, from planning and design, all the way to building maintenance.

A method of virtual design and construction, BIM charts a project’s lifecycle and can also help with mitigation and planning errors. It can also assist property managers in mapping all services and fixtures from the original construction details. This can help builders and managers efficiently predict and automate maintenance schedules for the entire lifetime of a building.

In addition to faster calculations, BIM software can quantify costs, and map all viable options available to execute a piece of work. Additionally, with BIM, you can make models that have several dimensions of project information, including:

- 3D BIM, which can be used to assess the constructability of a building before the project is executed.

- 4D BIM, which enables visualization of the building model over time by simulating the construction process.

- 5D BIM, which assists with early budget estimations, incorporating higher levels of detail and accuracy.

- Mobile technology, IoT, and smart devices

Mobile technology, IoT, and smart sensors are being utilized across the construction industry to streamline workflows more efficiently. They have the potential to help in the rapid transfer of data, management of files and drawings, tracking expenses, making accurate reports and calculations on-site, and recording labor and equipment hours. These devices are also playing a role in sustainability by helping the industry reduce its paper usage.

- Smart devices and wearables: As IoT devices can communicate with each other much faster than traditional methods, they can connect your construction site, turning it into a web of trackable devices that are easily accessible and controlled from a single office. They are increasingly being used on construction sites for worker-safety, cost reduction, quality assessment, and energy efficiency.

- Connected hardhats: Wearable tech has already infiltrated the personal gadget space, but wearable devices in construction can do more than just monitor heart rate or capture photos. A Japanese company has recently launched a standard hardhat that can monitor location, motion, and temperature, enabling it to issue a warning when a worker might be lightheaded or overheated. It can also perceive if a worker has fallen and trigger an emergency call to first responders. The exactness of the data collected also makes it possible to perform better assessments of worksite mistakes to help prevent repeat occurrences.

- Smart boots: Another wearable tech advancement, smart boots can also measure worker fatigue to alert first responders in an emergency, as well as communicate with heavy equipment to prevent vehicle accidents. The boots are powered by the energy generated by a worker’s steps and are equipped with RFID devices. These technologies can immediately identify workers when they enter the site and make it possible for site managers to automatically assign tasks over mobile devices.

- Smart infrastructure: Structural monitoring systems use sensors to monitor the strengths and weaknesses of a given structure that are invisible to the human eye. These monitors can help predict structural problems before they happen, allowing the site owner to bring in a construction crew to perform necessary maintenance before the site becomes dangerous.

- Virtual, Augmented, and Mixed Reality

The introduction of augmented reality (AR), virtual reality (VR), and mixed reality (MR) to construction has brought a huge shift in the way companies consume and interact with data. Walking through a property with the assistance of VR headgear can provide an immersive look into what the project could look like upon completion.

Whilst VR is useful during the pre-construction stage, AR comes into play once the project has begun. With a smartphone or tablet, 3D models can be merged onto real-time images of the project as it stands on a site. This can offer clients and construction companies a detailed future view of a building. AR technology also makes it possible to generate 3D models on top of a 2D plan, allowing for more accurate architectural planning.

- Advanced constructional materials and resources

It’s not only equipment and software that are advancing construction technology but building materials and resources are innovating as well. In an effort to construct more sustainably, reduce pollution, and cut costs, scientists are producing high-tech building materials of the future.

Some examples include:

- Self-healing concrete: Self-healing concrete repairs its own cracks and can last up to 200 years without replacement.

- Translucent wood: Translucent wood offers an alternative to window glass and is stronger and more biodegradable.

- Recycled bricks: A new type of brick made of wool and seaweed is 37% stronger[4] than traditional earth brick and doesn’t need to be fired in a carbon-emitting kiln.

- Algae-infused materials: Algae-infused building panels and invisible solar cells have the potential to generate clean energy.

- Grasscrete: As its name might indicate, grasscrete is a method of laying concrete flooring, walkways, sidewalks, and driveways in such a manner that there are open patterns allowing grass or other flora to grow. Whilst this provides the benefit of reducing concrete usage overall, it also offers improved stormwater absorption and drainage.

- Recycled plastic: Instead of mining, extracting, and milling new components, researchers are creating concrete that includes ground-up recycled plastics and trash, which not only reduces greenhouse gas emissions but also provides a new use for landfill-clogging plastic waste.

- Mycelium: Mycelium is a futuristic building material that comprises the root structure of fungi and mushrooms. Mycelium can be encouraged to grow around a composite of other natural materials, like ground-up straw, in molds or forms, then air-dried to create lightweight and strong bricks or other shapes.

- Ferrock: Ferrock uses recycled items, including steel dust, to create a building material that is even stronger than concrete. What’s more, ferrock actually absorbs and traps carbon dioxide as part of its drying and hardening process – making it not only less CO2 intensive than traditional concrete, but actually carbon neutral.

- AshCrete: AshCrete is a concrete alternative that uses fly ash instead of traditional cement. By using fly ash, a by-product of burning coal, 97% of traditional components in concrete can be replaced with recycled material.

It is undeniable that digitalization allows for greater collaboration and information management. With new technologies redefining engineering practices, it makes sense for construction businesses to incorporate digital processes to evolve, compete and survive in the industry.

As the country strives to fulfill the ambitions of Vision 2030, it stands at strategic crossroads. The global construction industry readies itself for a bolder and braver future – one that is not only more digitally empowered but also environmentally friendly. Saudi’s construction sector to stands to gain a lot from innovating itself. By choosing the right technologies and taking a forward-oriented approach, it can become the industry leader.

Digital innovations like BIM, VR, drones, 3D mapping, 3D printing, and mobile technology are the future. They can help companies like yours offer competitive options to clients. Now is the time to consider whether adopting certain digitalization technologies is right for your business’s future.

For information on technologies changing Saudi construction, or to find out how Binex can help support you with digitalization across your projects, get in touch here.